CNC Machinist

CNC machinists are highly skilled tradespeople, and a successful career will depend on a mix of technical competencies and soft skills.

They understand how material properties, tool design, cutting speeds, and workholding techniques work together to achieve optimal surface finish, dimensional accuracy, and efficient cycle times.

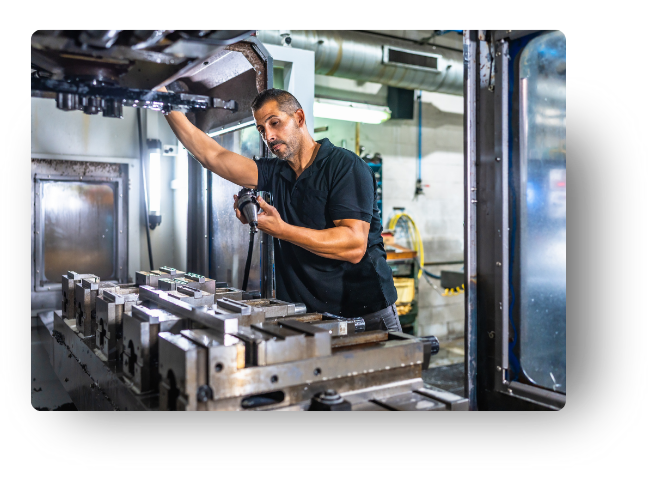

CNC Machinists are skilled professionals who use computer numerical control (CNC) machines to manufacture precise, high-tolerance parts from metal, plastic, and composite materials. They interpret engineering drawings and manufacturing documents—often following ASME Y14.5 or ISO-GPS standards—then set up machines, choose tools, run programs, and inspect parts during production.

Across industries such as aerospace, medical devices, and biotechnology, machinists ensure every part meets rigorous quality and regulatory standards, including AS9100 and ISO 13485. They operate advanced multi-axis mills, lathes, and Swiss-style machines, making precision adjustments and confirming tool paths. Using instruments like micrometers, calipers, height gauges, and CMMs, they inspect each component for accuracy. Their quick detection and correction of dimensional variations help maintain part quality and prevent future issues.

CNC machinists do more than run machines—they are process owners. They understand how material properties, tool design, cutting speeds, and workholding techniques work together to achieve optimal surface finish, dimensional accuracy, and efficient cycle times. In dynamic, high-mix, low-volume settings, they work closely with programmers, engineers, and quality teams to refine setups, minimize waste, and ensure every part meets customer requirements.

Top Skills and Qualifications for CNC Machinists

CNC machinists are highly skilled tradespeople, and a successful career will depend on a mix of technical competencies and soft skills.

| Technical Skills | Soft Skills |

|

Blueprint reading GD&T interpretation Tool selection Fixture setup CNC control navigation Basic CAM understanding Manual inspection Precision metrology |

Attention to detail Spatial reasoning Problem-solving Collaboration Communication Self-sufficient |

An effective CNC machinist has strong mechanical skills and a deep understanding of machines and tooling. They handle routine maintenance—such as refilling cutting fluids, clearing chips, and checking tool wear—and can troubleshoot basic issues like recalibrating a tool setter or adjusting a clamp. In smaller shops, machinists may also be responsible for minor repairs and for coordinating with technicians on larger maintenance tasks. This expertise helps keep production operating smoothly and allows machinists to quickly spot and address any abnormal machine behavior.

Machinists need strong math skills, including arithmetic, algebra, geometry, and trigonometry. They use these skills to calculate hole locations, set tool paths at specific angles, and convert units and tolerances as needed. Many employers specifically look for machinists with a solid understanding of trigonometry.

Reading and interpreting blueprints is a core skill for machinists. In precision industries, machinists must be able to understand Geometric Dimensioning and Tolerancing (GD&T) symbols and tolerances to ensure their machine settings produce parts that meet exact specifications. Employers often look for candidates who can confidently read blueprints and engineering drawings, and may test for this skill during the hiring process.

While not every machinist role requires full CAM programming, a strong understanding of G-code and M-code is essential. Machinists often make on-the-fly edits to CNC programs, such as adjusting bore sizes or feed rates. Top candidates may have experience writing simple programs or using CAM tools. Familiarity with CAM and CAD software, like Mastercam or SolidCAM, is highly valued. Machinists who can read code and understand program flow are better equipped to troubleshoot and resolve issues efficiently.

Tools and Technologies for CNC Machining

CNC machinists work within a connected environment of software, machinery, and advanced technology to manufacture precision components. Mastercam is commonly used to generate toolpaths, while SolidWorks supports CAD model interpretation and modification. For complex multi-axis or Swiss-style machining, machinists may also use Esprit to handle intricate programming requirements.

Job tracking and production scheduling are managed through ERP systems that link machining operations to customer orders and quality documentation.

On the shop floor, machinists operate a range of equipment, including 3-axis and 5-axis mills, CNC lathes, Swiss lathes, and mill-turn centers, often supported by coordinate measuring machines (CMMs) for inspection.

- Machines – 5-axis mills, 3-axis mills, lathes, Swiss lathes, mill-turns, CMMs

- Software – Mastercam, SolidWorks, Esprit, shop floor management, ERP, 1Factory

The landscape is rapidly evolving—robotic part loading is reducing manual handling, in-process probing is enabling real-time dimensional feedback, and AI-driven tool wear prediction is helping machinists extend tool life and prevent scrap. Digital twin simulation is also gaining traction, allowing machinists to visualize and validate machining processes before a single chip is cut.

Career Trajectory for CNC Machinists

Career progression for CNC machinists follows a structured path that rewards technical mastery, process ownership, and leadership initiative.

Most begin as apprentices or operators, learning machine controls, basic setups, and inspection techniques under close supervision.

With experience, they advance to setup machinists who handle complex tooling arrangements, multi-axis configurations, and first-article inspections.

Lead machinists take ownership of entire cells, troubleshoot process issues, and coordinate with programmers and engineers.

Senior machinists are recognized for their ability to run high-precision jobs independently, train others, and contribute to continuous improvement.

Lateral moves into CNC programming, quality inspection, or manufacturing technician roles are common for those who develop strong CAD/CAM or metrology skills. Leadership opportunities include cell lead, shop supervisor, process improvement coordinator, and training mentor—roles that blend technical depth with team management and cross-functional collaboration.

Salaries and hourly rates range drastically depending on skillset and experience. This table provides an overview of salary ranges, based on specific roles.

| Apprentice | $18 - $22 |

| CNC Operator (varying levels commonly shown as CNC Machinist I, II, and III) | $20 - $26 |

| CNC Setup Machinist | $26 - $32 |

| Lead Machinist | $32 - $38 |

| Senior Machinist | $34 - $40 |

Education and Training

There are many ways to develop the necessary skills needed to have a successful career as a CNC machinist. In addition to many online, and often free, learning resources, students and young professionals can participate in local educational and training programs.

For example, Colorado is home to many CNC machinist training programs, including:

- Front Range Community College’s (FRCC) Precision Machining Technology program

- Red Rocks Community College’s (RRCC) Precision Machining program

- Pickens Technical College basic machining course

In addition to online learning resources and formal training programs, students and young professionals can also take advantage of apprenticeship programs and industry-recognized certifications.

Interested in learning more about CNC machining career opportunities? Contact our recruitment team!